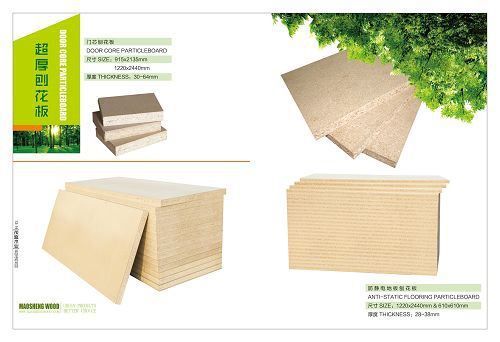

Particle board, fire seal, fire door, melamine chipboard, hollow core--FULIN WOOD GROUP

Particle board, fire seal, fire door, melamine chipboard, hollow core--FULIN WOOD GROUP

The laboratory is equipped with the internationally advanced Grecon density profile analyzer; the physical and mechanical testing of the product is tested every 1.5 hours to ensure the stable quality of the products.

How to make best quality fire retardant chipboard?

The production of fire retardant chipboard can be divided into intermittent flat pressing method and continuous production extrusion method and rolling method according to different slab forming and hot pressing equipment. In actual production, flat pressing method is mainly used. Hot pressing is a key process in particleboard production. Its function is to solidify the rubber material in the slab, and to solidify the loose slab into the plate with specified thickness after being pressurized. The technological requirements are as follows: 1) proper moisture content. When the moisture content of the surface layer is 18-20%, it is beneficial to improve the bending strength, tensile strength and surface finish, and reduce the possibility of blistering and delamination during pressure relief.

The moisture content of the core layer should be lower than that of the surface layer to maintain the appropriate plane tensile strength. chipboard in the thickness direction increases, and the plane tensile strength decreases significantly. After hot pressing, the fire retardant chipboard should be treated for a period of time to make its moisture content reach the equilibrium state, then saw and sanded, and the packaging was inspected. But it can't stack in hot state after pressure relief, otherwise it will increase the brittleness of the plate. Molding technology refers to the technology of forming products in one operation. There are three mature processes. The hot mold method can use less or no glue, and it can be glued by activating the lignin flow in the closed hot mold, but it needs to be cooled and demoulded, with high heat consumption and low productivity, which has been gradually eliminated. The box forming method is to use special press to pressurize and press into products at one time, which is used to manufacture packing boxes. The hot pressing method is mainly used to manufacture furniture accessories, interior decoration accessories and pallet, etc. the adhesive is mainly urea formaldehyde resin, and the surface of the fire retardant chipboard is pasted with veneer or resin impregnated paper for one-time molding. In addition, there are also the plane die pressing method, in which the surface of the fire retardant chipboard has been made or the forming slab without hot pressing is pressed with a template to make relief patterns.

FAQ

1) Which wood do u use to produce fire rated particle board?

We use china poplar to make fire rated particle board.

2) How many type do u have of the fire rated particle board?

We have fire rated 30mins ,60mins .90mins and 120mins .

3) Which fire rated certificate u have?

We have got IFC , CERTIFIRE , INTERTEK CERTIFICATE.

Hot Tags: fire retardant chipboard, China, manufacturers, suppliers, factory, made in China, Carb Particle Board, Holow Core Door Blank, Fire resistant chipboard, WOODEN FIRE DOOR, NFR door leaf, hollow core chipboard